Anyone in the mining industry can tell you just how demanding it is. No matter what projects you're working on or the size of the site, mining teams need patience, expertise, and a wide array of different mining equipment to do the job right.

Here, we'll look at that equipment and tell you how miners use each piece and where they're most valuable.

⛏️ Different Fields in The Mining Industry

Before breaking down the several types of mining equipment and identifying which ones you'll need for your mining operation, it's vital to first look at the two main fields in the mining industry: underground mining and surface mining.

Not all types of mining require the same specific tools. Therefore, depending on your goals, you won't need to bring all your equipment to the mining site.

Surface Mining

Surface mining is a mining operation that happens on ground level rather than in a cave.

Statistically, surface mining is more common and efficient than underground mining operations, though the two are vastly different processes.

Surface mining operations uncover roughly 97% of all mined materials, primarily due to the flexibility of the surface mining process.

Miners can unearth surface material through strip mining, quarrying, and open-pit mining.

In addition, those different mining methods bring various mining equipment into the enclosed environment of underground work, such as massive earth-moving trucks and rotary drill rigs.

Surface and blast mining often go hand-in-hand since there's less risk of an accident when you use explosives to loosen rocks above ground.

Underground mining techniques also rely on blast-specific tools, but those methods are less hazardous in open spaces.

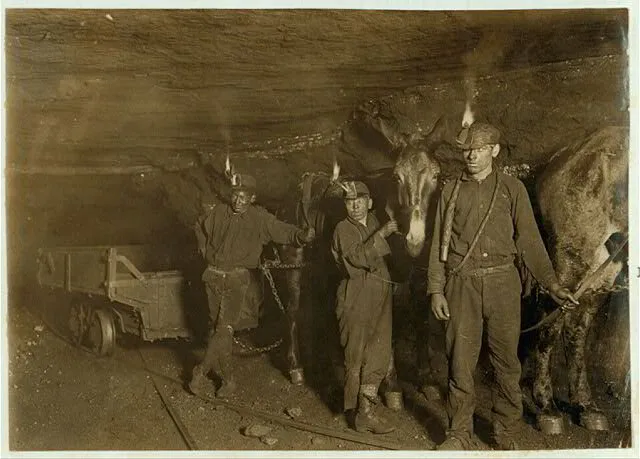

Underground Mining

Underground mining is the part of the mining industry outsiders first think of, despite being less common than mining for surface material.

Unlike surface mines, which benefit from open areas, fresh air, and a soft digging surface, underground mines are confined spaces surrounded by hard stone requiring unique tools to conquer.

For example, while surface miners have to cut through thin layers of soil for a portion of their work, underground miners have to saw through a much more rigid material.

As a result, underground miners need equipment that can cut through hard rock and heavy-duty mining equipment that can fit into tight quarters.

Additionally, underground mining requires mining machines that don't emit hazardous fumes.

Because of the cramped space and lack of fresh air in underground mines, those emissions will create health hazards that don't exist in surface mines.

In other words, you will need strong equipment that can drill through hard rock but is safe for your underground mining site.

Meanwhile, you won't have to limit your tools as much for surface mining, and you'll likely need more mining machines than you would underground for the various mining methods you can employ above ground.

Common Types of Underground Mining

Despite underground mining being traditionally more dangerous and demanding than above-ground mining, there are two common types of cave-mining strategies that make the process easier: room and pillar mining and retreat mining.

- Room and pillar mining aims to create more space within underground mines while leaving enough support pillars to keep the cave from collapsing. That way, the miners have more room for equipment and drilling out mined minerals and can minimize the potentially harsh conditions of working in a cramped space surrounded by hard rock.

- Retreat mining is a mining method that happens after room and pillar mining and is when miners return to underground mines to remove the pillars and pull out as much material as possible. However, the retreat method only works if the mining site is secure enough to stand without natural support.

⛏️ Surface-Level and Underground Mining Equipment That You Need

Now that we've looked at the differences between the two most common fields in the mining industry, we can break down the mining equipment necessary for each.

While some of the mining machines below won't apply to every mining method or subset, others are universal, and your miners should bring them wherever they're working.

Mining Trucks

No matter where you're digging, you'll have to relocate heavy loads of dirt, hard rock, and ore to keep a clean workstation and preserve your mined materials.

Mining trucks are the most efficient tools for removing those substances, making them the most commonly used machinery in the mining industry.

Due to their importance, mining trucks come in several sizes and diesel or electric models to fit with underground or open pit mining.

Regardless of size or model, mining trucks come with large, high-strength tires and frames that are perfect for material handling.

Meanwhile, traditional recreational trucks don't have the strength or build to handle mining material and fall flat on dig sites.

What Sets Mining Trucks Apart

Most mining trucks can carry up to 400 tons of equipment or minerals, regardless of the climate or dig conditions.

Miners work year-round and across the globe, so manufacturers build their trucks to withstand heavy heat, cold, and even dust and rainstorms.

Additionally, these trucks can easily drive over rocky terrains or up and down steep hills.

Hydraulic Mining Shovels

Hydraulic mining shovels (commonly called "hydraulic excavators") are motorized tools that dig through and remove tons of material from a dig site.

They typically have wheels or tracks to navigate the mine, a large shovel at the front, and a driver within the built-in cab to operate the machinery.

Because of their size and dirt-digging design, miners commonly use hydraulic mining shovels for open pit and surface-level strip mining rather than underground mines.

How to Use a Hydraulic Mining Shovel

In addition to digging up dirt and relocating material, miners can use hydraulic shovels to move resources into trucks or loaders and open up new dig sites.

Continuous Mining Machines

Continuous mining equipment uses steel and tungsten cutting tools to drill through soft material without constant input from a miner.

It is particularly popular in the coal mining industry since manufacturers build continuous mining machines to cut through the material.

Benefits of Using Continuous Mining Machines

The primary appeal of continuous mining equipment is that it handles the most time-consuming job of mining without user input.

Instead, miners can start the machinery, let it run on its own, and focus on other duties to finish the job faster.

In addition, most continuous mining machines are electric so that miners can use them safely for underground work and strip mining.

Roof Bolters

When you drill holes in an underground mine without staying cautious, you'll weaken it and increase the odds of collapse.

Roof bolters are a line of defense against that risk. They prop up the mine while you're working so that you can continue drilling without worrying about a cave-in.

Some miners also connect a safety net to their roof bolters to catch potential debris.

You'll only need this mining equipment if you're digging underground or are blast mining on the surface near high walls that could collapse.

Electric Rope Shovels

Electric rope shovels resemble hydraulic mining shovels with tracks or wheels, a large shovel, and a driver inside the equipment.

For starters, electric rope shovels use electricity rather than diesel, so they won't emit toxic fumes that could harm mine workers.

Additionally, the shovel moves with a rope-and-pulley system.

How to Use an Electric Rope Shovel

You can use an electric rope shovel similarly to how you would use a hydraulic one (for example, moving debris to a designated waste area).

Blasting Equipment

Miners use blasting tools to soften ore and rocks that traditional drill bits can't force out of place.

Miners also use these tools to blast unwanted material standing in the way of more valuable ore out of place.

You can use blasting tools for above or below-ground mining. However, you can create a cave-in with careless blasting in underground caves, so remain cautious and only use reliable equipment.

Types of Blasting Equipment

- Charging equipment

- Blast charges

- Remote detonators

- Personal protective gear

Crushing Equipment

It's easy to move material and sort through ore when you break it up into smaller bits first, which is why the mining industry has created several crushing tools.

You can use these tools for underground and surface mining to break large rocks into manageable pieces that your trucks, mining shovels or conveyors can carry away.

Mining Drills and Drill Rigs

Drills carve through whatever mine material is standing in your way, primarily to provide space for blasting charges to loosen up ore or overburden, or for core retrieval to find out what's hidden in the ground.

There are two main types of drilling tools in mining: rotary drill rigs and hammer drills. Rotary drills can drill holes through rocks by wearing down a small area and sending air through it to blow dust out of the space.

Meanwhile, hammer drills are better for drilling through the softer ground and work similarly to rotary drills but are slightly smaller.

How to Use Mining Drills and Drill Rigs

You can use either of these mining tools to create small pockets for blasting equipment.

A dedicated, tucked-away area for your blast charges will keep them from damaging necessary parts of your worksite and make the charge more effective.

These drill tools are also helpful for production drilling, a practice where miners create wells to look for oil and gas.

Mining Dozers

Mining dozers are dual-purpose machines you'll commonly see on surface mining sites.

They are large vehicles requiring a dedicated driver that can move heavy material across a work area.

You can purchase dozers with either tires or tracks depending on the terrain you need to travel, and you can equip them with various attachments for unique jobs.

How to Use Mining Dozers

Depending on the attachment, mining dozers can complete any of the following tasks:

- Moving unwanted material aside to make room for a new worksite.

- Leveling the dirt around your worksite for a safer, more even mining job.

- Tearing soil and plants out of a large pit to reveal mineable material.

Motor Graders

Even while surface mining, you aren't likely to find a worksite with perfectly even terrain.

Unfortunately, that means you might lose material or see your vehicles slow down during transportation if the path to the processing site is too bumpy.

This is an especially significant worry with used mining equipment that might not have the strength to climb slopes or traverse uneven terrain.

Motor graders are valuable mining tools that overcome this issue by creating perfectly smoothed paths for your vehicles that are clear of obstacles.

They can push debris out of the way with one pass over a stretch of land and even create grooves in soft material like soil that drain out standing rainwater.

How to Use Motor Graders

Motor graders are most valuable when you use them before you begin mining.

Even if you don't need other motorized tools until the end stage of your work, paving a smooth path early can ensure smooth foot traffic and protect your crew from tripping hazards.

Dragline Excavators

Dragline excavators are massive mining tools that help miners quickly relocate materials to the right areas.

Though their size prevents them from fitting in underground mines, they are valuable parts of all surface-level operations.

Dragline excavators are vehicles with a large crane at the front and a massive, swinging bucket attached.

The excavator driver lowers the crane into piles of ore or unwanted material, the bucket scoops up large portions of the debris or minerals, and the driver then dumps them in the proper area.

These tools also run on electricity, so they don't produce carbon emissions locally.

How to Use Dragline Excavators

The most effective use for dragline excavators is to treat them like a debris remover.

For example, if your worksite has tons of dirt or rocks piled up after digging, you can use the excavator to pile the resources in the waste area or your mining truck for further transportation.

Additionally, since dragline excavators have such a high reach, you can use them to remove material from large walls that your other mining equipment cannot reach.

Wheel Tractor Scrapers

CC Image by Mike Liu via Flickr.

Wheel tractor scrapers are similar to motor graders in that they can smooth out the ground around your worksite.

However, the critical difference between these tools is that wheel tractor scrapers collect the debris with a built-in bin rather than pushing it aside like a motor grader.

How to Use a Wheel Tractor Scraper

The bin on the tractor scraper lowers to ground level and scoops up resources, which is useful if you're looking to keep or relocate those materials rather than simply brushing them aside.

They're also helpful for starting surface-level mines and basic, soft-material digging tasks.

Analysis Tools

Every mining operation needs a list of analysis tools to ensure they're acquiring the right resources, confirm those resources are the proper size and weight, and ensure they reach the correct location.

Common Types of Analysis Equipment

- Weightfeeders: Weightfeeding tools attach to your conveyer belt and material crushing equipment. They analyze the size of the materials passing through and adjust the crusher's settings to shape everything properly.

- Crossbelt Analyzers: These tools monitor your site's automatic sorting equipment to ensure every resource finds its proper spot.

- Flow Measurement Tools: These automated machines look at your free-falling materials' flow rate in real-time so you can keep efficiency up and your product quality high.

⛏️ Longwall Mining Equipment

Longwall mining is another type of underground mining focusing on harvesting material from an elongated wall. Longwall sites often pull from walls roughly 2.5 miles long and need several different tools to pull it off.

Plow

Longwall plows travel the length of the wall (in most cases, a coal wall) and cut the resources from the surface. The material then falls onto a conveyer belt directly below the wall for the next phase.

Conveyer Belt

The conveyer belt sends minerals from the dig site to its next location, often either the material handling or material processing site. Conveyer belts are helpful for surface mining projects as well.

Roof Supports

Roof supports ensure the mining location doesn't cave in during longwall mining operations. Typically, longwall miners use roof bolters rather than longwall-specific supports.

⛏️ Learn More About Running a Successful Mining Operation at An Underground Miner

An Underground Miner is your one-stop resource for everything you need to know about underground mining.

We have several resources on our website for new and experienced miners looking for more information on what mining equipment they need, how the mining industry is evolving, who the most reliable brands in mining equipment are, and even more.

Join us on Facebook today to get in on the conversation.

This article was written by An Underground Miner