Permanent magnet motor rotor for automobile

A technology for permanent magnet motors and rotors, which is applied to the rotating parts of the magnetic circuit and the shape/style/structure of the magnetic circuit. Effects of reducing system cost, increasing reluctance torque, and increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

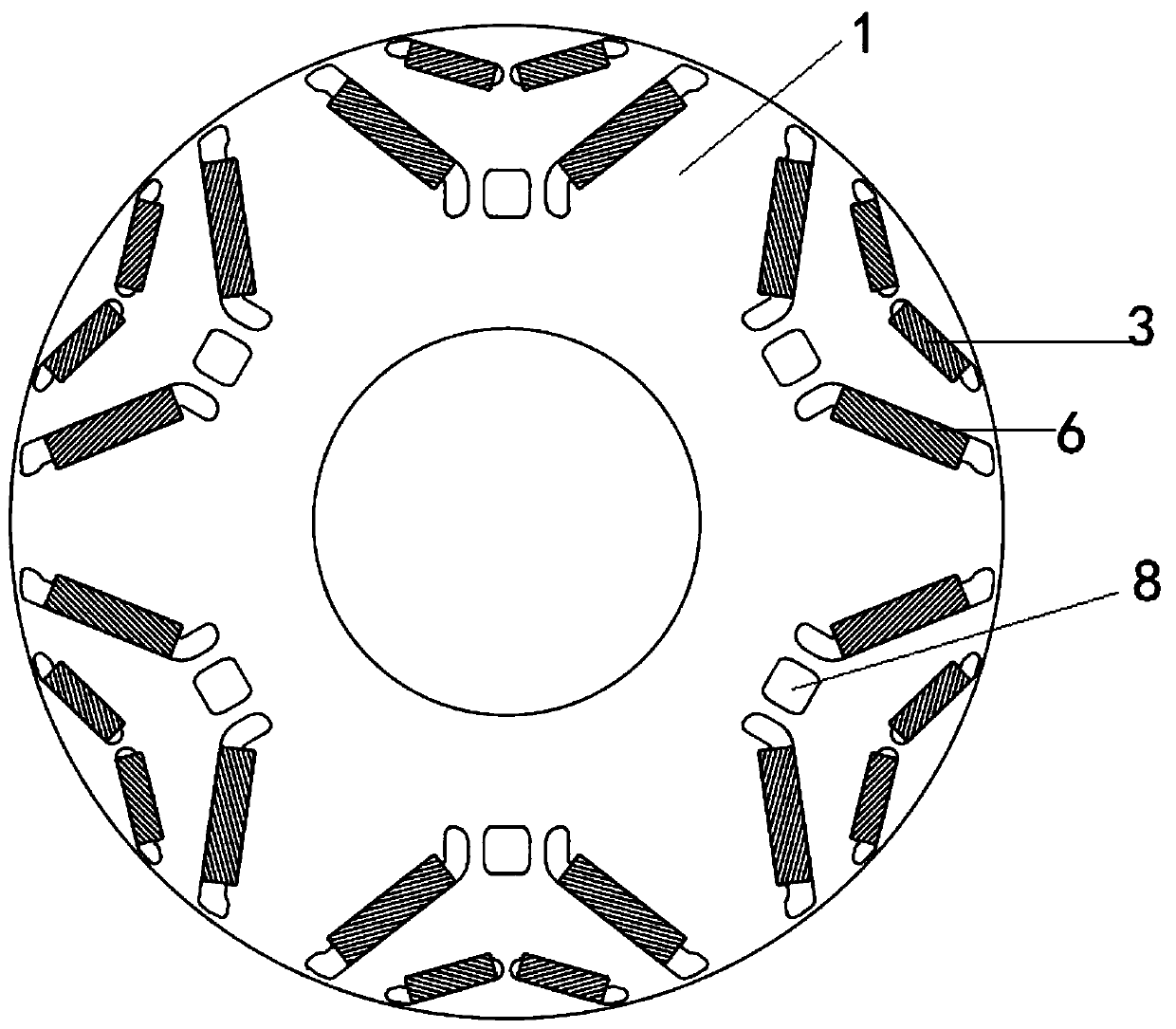

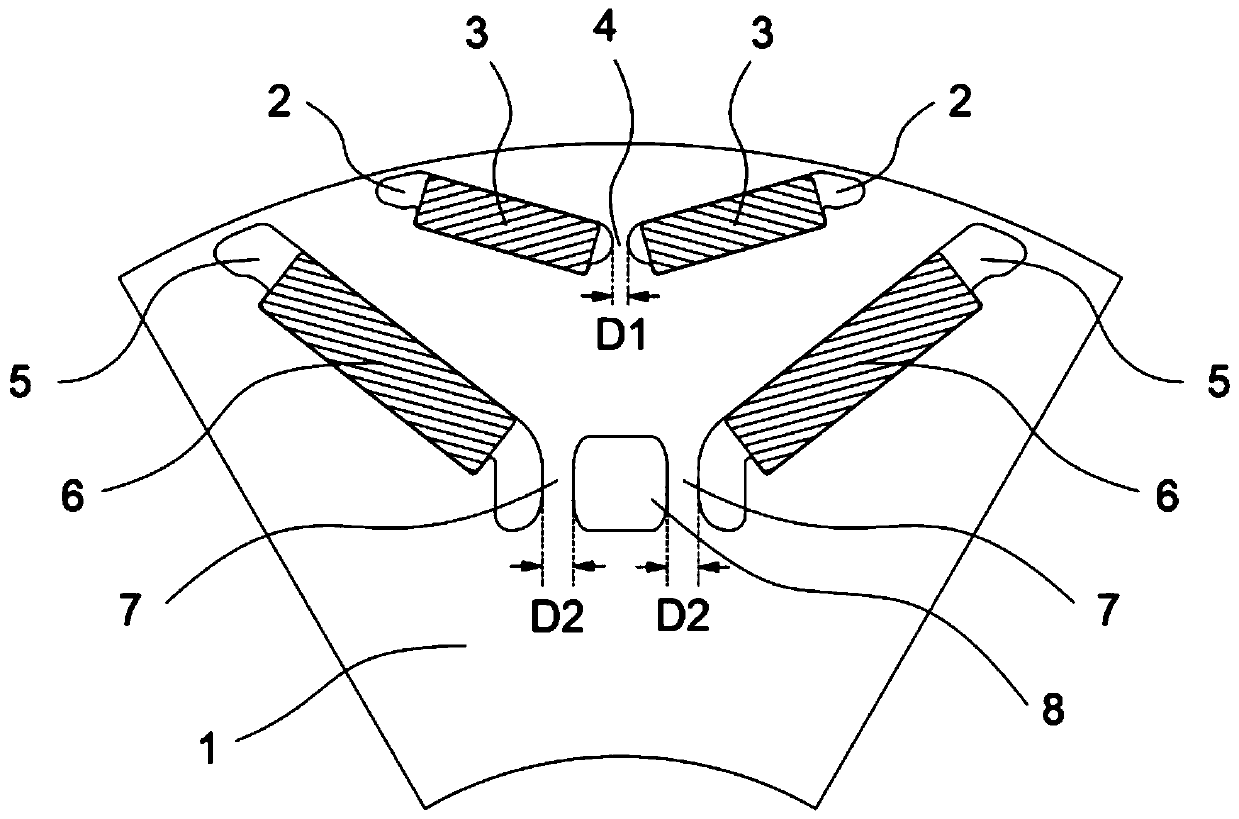

[0016] like figure 1 , 2 As shown, the present invention provides a double-layer V-shaped rotor topology, including rotor core 1, upper magnetic steel slot 2, upper magnetic steel 3, upper auxiliary magnetic bridge 4, lower magnetic steel slot 5, lower magnetic steel Steel 6, lower auxiliary magnetic bridge 7, auxiliary air slot 8; on the basis of the traditional V-shaped topological structure, a double-layer V-shaped topological structure is derived. At the same time, in order to ensure the structural strength of the rotor under high-speed conditions and reduce the risk of demagnetization, the scheme optimizes the single magnetic bridge structure in the V-shaped structure of the lower layer to a parallel parallel magnetic bridge structure, and optimizes the size of the auxiliary air slot between the double bridges. Excellent design. Compared with the traditional single-V topology, the weight of each magnetic pole of the double-V topology is larger, which puts forward higher...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap