Electrical insulators are safety devices that restrict and separate the flow of voltage to defined areas of a circuit. They are commonly applied to outdoor electrical networks such as public utility lines.

Table of Contents

What is an Electrical Insulator?

An electrical insulator is a hardware accessory applied to low voltage, medium voltage, and high voltage electrical systems operating in public services, such as overhead transmission and railway lines. They help to enable the smooth and safe functioning of the electrical system.

Electrical insulators are crafted from a range of non-conductive, durable materials such as glass, porcelain, and composite polymer to ensure that the insulator can consistently maintain a high level of resistivity (voltage resistance).

Types of Electrical Insulators

Electrical insulators come in different sizes and designs to suit the varying voltage and fixture needs of different power systems. As they are installed outdoors in all seasons, most electrical insulators incorporate shells or ‘petticoats’ into their designs to ensure that they stay dry and non-conductive during wet conditions.

The most common types of insulators used to assist overhead power lines are: i) pin insulators; ii) post insulators; iii) spool/shackle insulators; iv) stay insulators; and v) suspension insulators.

Pin Insulator

Definition

Believed the earliest type of insulator developed for overhead transmission lines, pin insulators isolate a conducting wire or cable from the rest of the network. They are shaped to enable the secure fastening of the insulator to a conductor wire, making it easier to contain it.

Pin insulators are primarily used in electrical systems with a voltage load up to 33 kV. In contrast to some other insulator types, pin insulators are fixed directly on the structure.

Features

Pins insulators are of a single-layered petticoated design arranged on a pin, which allows their tip to connect easily to a conductor element. Depending on requirements, they can be of a single or multi-pin variety and are usually crafted from either glass or porcelain.

Hardware

Pole top pins are used to support the connection of the pin insulator directly onto the pole. They are sometimes further reinforced with bolts.

Top ties and side ties secure conductors to insulators. Top ties secure conductors at the top of insulators, and come in different sizes to accommodate different shaped insulator heads. Side ties are designed to fasten conductors to the side of insulators by slotting into a built-in groove in the insulator.

Post Insulator

Definition

Post Insulators have been used in overhead transmission lines for almost a century. Larger than pin types, they are used as both an insulator and to add reinforcement to vulnerable areas of an electrical system.

In modern times, post insulators are often used in place of pin insulators on voltage loads up to 69 kV, with solid core versions able to withstand up to 1100 kV.

Features

Post insulators have a clamp at both their top and bottom end, and can be mounted either vertically or horizontally as needed. Due to their size, they have a greater number of petticoats than pin types in order to maintain their insulating capacity in wet climates.

Hardware

Insulator brackets are often used to securely mount post Insulators between 15 Kv – 34.5Kv directly onto the pole itself. They act as a sturdy brace for the insulator and remove the requirement to involve cross arms in the installation.

Spool Insulator

Definition

Also known as shackle insulators, spool insulators are used on lines with a low voltage load. They are versatile enough to offer insulation to both primary and secondary conductors on a power line, and can be mounted horizontally or vertically.

Spool insulators work with a number of other hardware components including secondary racks, secondary clevises, spool ties, and upset bolts.

Features

Spool insulators have a central hole to facilitate the mounting of the insulator. The hole is also tapered to help reinforce the insulator and minimise the risk of it becoming overloaded with voltage.

Hardware

Spool Tie is used with spool insulators to provide protection to bare conductor cables against motion and damage in harsh climates, especially within wider line angles. Tie tubes can help to further protect fragile lines from the spool bind.

Secondary Racks are steel-based cables which are mounted with spool insulators to provide structural reinforcement. They are forged in a U-shape to mold to the contours of the pole easily during the mounting process.

Secondary Clevises (also known as D irons) are flat steel brackets which help to secure spool insulators to poles in awkward locations, such as dead ends and corners. Their slotted design enables mounting without disturbing any insulators already installed.

Upset Bolts are a type of fixing which help to support connectors by stabilising the position of the insulator. Upset bolts come in single or double versions to support more than one connector at a time.

Stay Insulator

Definition

Stay insulators (also known as egg insulators owing to their shape) are insulators designed to protect and contain low voltage stay wire by acting as a counterbalance against dislodging or a sudden voltage change.

Particularly useful for dead-end poles, stay insulators prevent the loose or overloaded wire from coming into direct contact with the ground or other surfaces where it could become hazardous.

Features

Stay insulators are a type of strain insulator, designed to withstand extra line pull tension. They are oval-rectangular in shape, with a central hole for threading. Due to their protective function, stay insulators are always installed between the conductor and the earth.

Hardware

Stay wire is used in partnership with stay insulators on pole lines to help to stabilise any extra electrical and mechanical tension on the poles.

Suspension Insulator

Definition

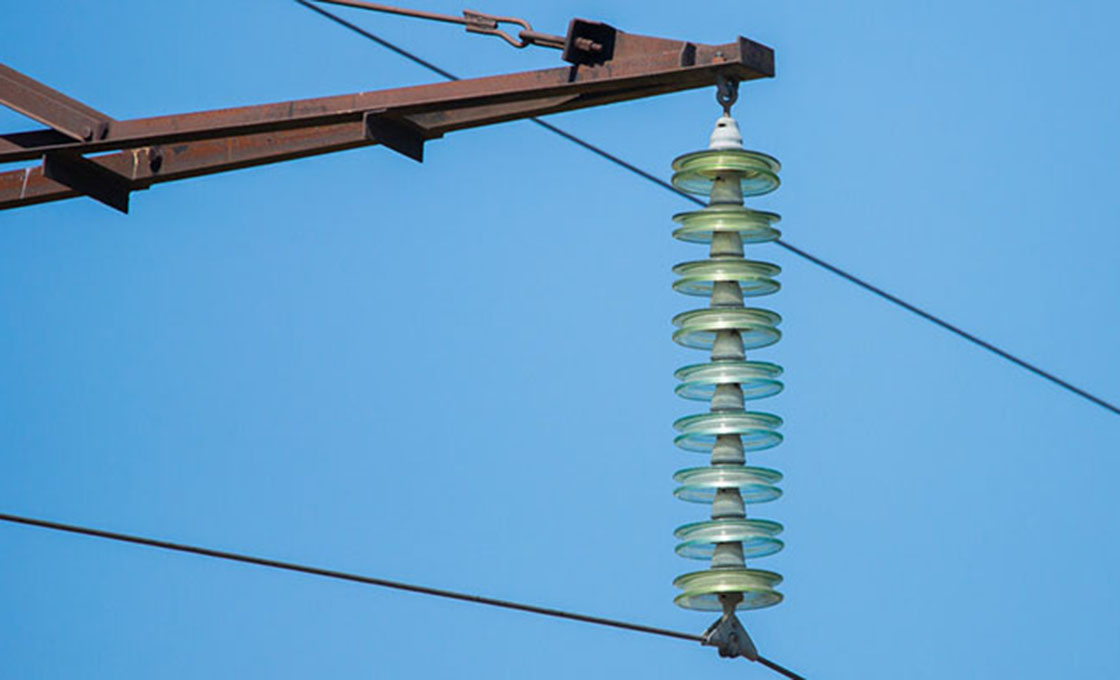

Suspension insulators are modular insulators that help to protect a power line from overloading using a conductor suspension method.

Primarily applied to networks with a voltage load of 33 Kv and above, a conductor is attached to the bottom end of the insulator and suspended from it, separating that conductor from others on the line.

Features

Suspension insulators are designed similarly to a pearl necklace, with a number of insulator discs assembled onto a flexible insulator rod which allows the voltage load to be safely and evenly distributed across the discs. The insulator discs can also be removed and added to as needed without dismounting the insulator.

Hardware

Thimble Clevises are used as a reinforcement link between the suspension insulator and the line. Threaded through the insulator the clevis bears the stress load of the suspension, protecting the connector loop from damage.

Armour Grip Suspension is a form of suspension specifically designed to minimise the effects of movement, stress, and static load at the support point of the suspension. This minimises the risk of structural damage from kinking or flash over.

Choose a Professional Electrical Insulator Manufacturer

If you’re looking for overhead line insulators, High-quality insulator suppliers will have high production and technology capabilities. These guidelines will help you find the right overhead line insulator manufacturer.

- Verify if the company has a license

- The company’s production capacity

- Seek out reviews about the manufacturer

- The manufacturer’s experience

- Quality standards up to regional standard

As a reliable insulator manufacturer in China, RAX Industry can supply you with insulators for transmission lines and distribution lines. You can also request custom sizing. Contact us if you have any questions.

Final Thoughts

The vast network of live cables and wires which line our landscape continues to harness new horizons within the arena of electricity. Fresh ideas and innovations continue to enhance human life, inspiring us to explore new frontiers.

Insulators play a significant role in providing our engineers and equipment with that paramount barrier of safety and support, ensuring that the key balance between essential protection and expansive progress is always kept in equilibrium.

frequently asked questions (FAQ)

What is an Electrical Insulator?

An electrical insulator is a hardware accessory applied to low voltage, medium voltage, and high voltage electrical systems operating in public services, such as overhead transmission and railway lines. They help to enable the smooth and safe functioning of the electrical system.

Electrical insulators are crafted from a range of non-conductive, durable materials such as glass, porcelain, and composite polymer to ensure that the insulator can consistently maintain a high level of resistivity (voltage resistance).

Types of Insulators in Overhead Lines

Electrical insulators come in different sizes and designs to suit the varying voltage and fixture needs of different power systems. As they are installed outdoors in all seasons, most electrical insulators incorporate shells or ‘petticoats’ into their designs to ensure that they stay dry and non-conductive during wet conditions.

The most common types of insulators used to assist overhead power lines are; i) pin insulators; ii) post insulators; iii) spool/shackle insulators; iv) stay insulators; and v) suspension insulators.

Why electrical insulators are important?

Insulators play a significant role in providing our engineers and equipment with that paramount barrier of safety and support, ensuring that the key balance between essential protection and expansive progress is always kept in equilibrium.